HomeConveyor Metal Detector

Conveyor Metal Detector Manufacturers in Kanpur, Suppliers and Exporters in Kanpur

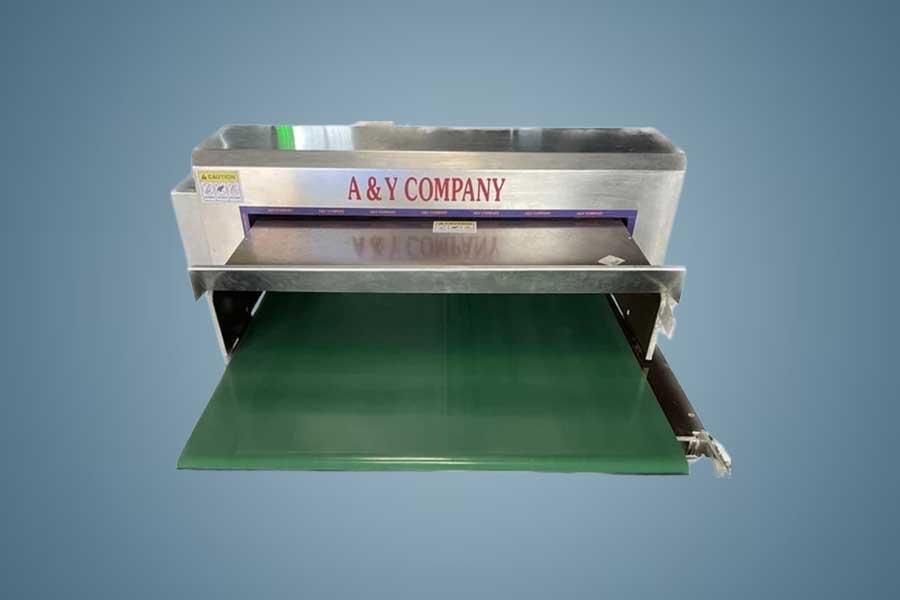

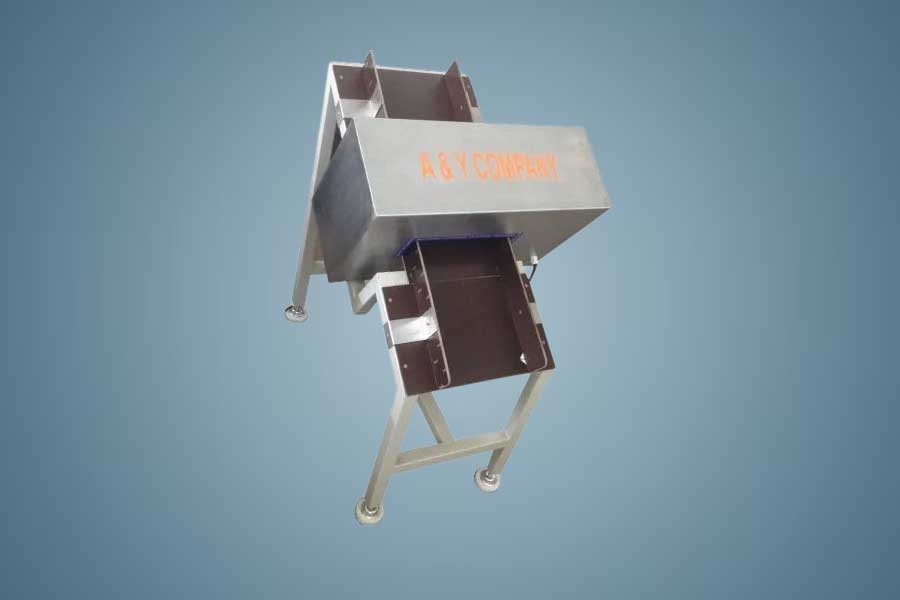

A & Y Company is a leading Conveyor Metal Detector Manufacturers in Kanpur, Suppliers and Exporters in Kanpur, has high-tech Conveyor Metal Detector systems which are intended to effectively identify and separate metal contaminants in the products being transferred on conveyor belts.Our detectorsare used to secure processing equipment, guarantee the quality of products and to maintain safety levels in the food, pharmaceutical, packaging and industrial sectors.Our solutions are constructed with strong construction and high sensitivity that has guaranteed good performance in heavy production conditions.

Details of Conveyor Metal Detector

As a leading conveyor metal detector Manufacturers in Kanpur, it is fabricated to locate metallic impurities in the products passing through a conveyor belt, without disrupting the normal production process.

The system comprises a transmitter coil, receiver coils, a control unit and a reject mechanism. The transmitter coil induces a high-frequency electromagnetic field inside the aperture of the detector. The electromagnetic balance is still maintained when a product that has no metallic components goes through this field.

When a metallic object (ferrous, non-ferrous or stainless steel) is placed in the field of detection, it disrupts the electromagnetic field. The resulting disturbance generates eddy currents on the metal, generating a second magnetic field. The electromagnetic signal is changed, and the receiver coils pick up this change.

Types of Conveyor Metal Detector

As a leading Conveyor Metal Detector Manufacturers in Kanpur, Suppliers and Exporters in Kanpur, we offer metal detectors of the following types:

- Soap Metal Detector

The metal contamination in soap bars and soap packaging lines. Acts as a guarantee of the purity of products and quality in the soap trade. - Vinyl Metal Detector

Screen metal particles in the roll, product and sheet vinyl product of the manufacturing process. Helps ensure that the products are of quality and there is no damage to equipment. - FIBC Bag Metal Detector

The device is used in the inspection of bulk materials filled in FIBC (Jumbo) bags with the view of checking whether they contain metal contamination. Guarantees good safety and compliance. - Needle Metal Detector

In the textile and garment industry, it is commonly used to identify needles and metal pieces that are broken. Avoids rejection of products and guarantees safety to the consumer. - Conveyor Belt Metal Detector

It is used to inspect goods that are on conveyor belts constantly so as to identify and eliminate metal contaminants. Ensures product safety, quality assurance and continuity of the flow of production. - Metal Detector of Flap Type Conveyor

It has an automatic flap reject system to automatically separate contaminated products. Perfect to use in high production lines with high speed that need accurate and dependable rejection. - Aggregate Conveyor Metal Detector

The device is used in mining and aggregate to identify large metal contents within a bulk material. Insures crushers, screens and conveyor systems against severe damage.

Technical Specification of Conveyor Metal Detector

As Pressure Conveyor Metal Detector in Kanpur, we have added below a table of technical specifications for this Detector.

| Parameter | Specification |

|---|---|

| Country of Origin | Made in India |

| Application | Soap Industry |

| Operating Voltage | 230 V AC |

| Power Supply | 230 V |

| Frequency | 50 Hz |

| Detectable Metal Types | Ferrous, Non-Ferrous & Stainless Steel (All Metals) |

| Alarm Indication | LED Visual Indicator & Audible Sound Alarm |

| Maximum Scanning Aperture | 500 mm (Width) × 100 mm (Height) |

Benefits of Conveyor Metal Detector

- Ensures Product Safety

Eliminates and filters any metal contaminants in products and eliminates injuries to the consumer and ensures safe end-use. - Improves Quality Control

Ensures uniform quality of products since foreign metal particles are detected during packaging or dispatching. - Protects Machinery

Eliminates harm to processing equipment that occurs due to the presence of metal fragments, to lower maintenance expenses and downtime. - Reduces Product Recalls

Early detection will reduce the chances of contaminated products being shipped to the market, and the brand image will be safeguarded.

Advantages of Conveyor Metal Detector

- High Detection Accuracy

Real-time sensing of ferrous, non-ferrous, as well as stainless-steel metal contaminants. - Continuous Inspection

Enables product continuous surveillance during conveyor belts without breaking production. - Auto-Cleaning of Contaminants

Reject systems are automated to isolate the contaminated products from the production line. - Reduced Human Dependency

Minimizes the effects of human error and labor expenses on manual inspection.

Uses of Conveyor Metal Detector

- Food Processing Industry

Identifies the presence of metal contaminants in food items like grains, snacks, bakery, frozen and packaged food. - Pharmaceutical Industry

Assures that capsules, syrups, tablets and powders are not contaminated with metal particles during manufacturing and packaging. - Packaging Industry

Checks the products that are packed to avoid the presence of metals before closing and shipment. - Textile Industry

Identifies broken needles and metal pieces in clothes and garments to prevent damage to its products and harm to the consumer.

A & Y Company is leading Conveyor Metal Detector Manufacturers, Suppliers and Exporters in Kanpur. We offer an effective and dependable method of identifying metal contaminants in continuous production processes. Our systems are of high sensitivity, durable construction, and easily integrated to assist industries in preserving product quality, safeguarding machinery, and complying with safety and compliance regulations. With stable performance and additional customization, A & Y Company can be trusted for reliable metal detection systems that help facilitate efficient operations and long-term sustainability.

FAQ’s

A conveyor metal detector works on a conveyor belt to remove any undesirable metal contaminants on products, thus ensuring the safety and quality of the products.

It can identify any kind of metals, such as ferrous, non-ferrous and stainless steel.